Visualising the future: challenges represent an opportunity for innovation

Paul Cook, Business Development Director – Renewables at Proserv emphasises that the rollout of new offshore wind developments needs to be matched by advances in operational processes.

The renewables space is an exciting place to be right now. Sustainable energy is our future and the scale-up has begun in earnest. The ScotWind leasing auction earlier this year, to give just one example, epitomised the appetite for harnessing the potential of offshore wind off the Scottish coast, with 17 projects awarded and an estimated future generating capacity of 25 gigawatts, more than two and a half times what is currently operating or presently in development in Scotland.

But the build-out is a complex and multi-faceted exercise necessitating that operational processes and backbone infrastructure to support the industry advance in step with new developments: so, increased capacity at harbours and ports, and targeted expenditure in upgrading transmission capabilities via the grid to avoid chronic supply chain pinch points in the future.

All this fresh investment is exciting and vitally needed to accelerate this sector, but if, at the same time, we do not develop the framework to smoothly transmit all the new electricity generated from point A to point B, then the journey would be severely undermined. Already, some of these factors are wisely being examined.

Similarly, to achieve such rapid growth, there will be a huge emphasis on equipment design and manufacturing. Industry analysts have predicted in the next decade alone close to 150,000 kilometres of assorted new cabling infrastructure will be installed.

Cable monitoring innovation

Today, cable failures and faults are already a real problem, so once we witness almost exponential growth over the coming years, this issue could signify a serious flash point lying in wait for owners and operators, creating major concerns over cable integrity, leading to frequent interventions and substantial lost revenue.

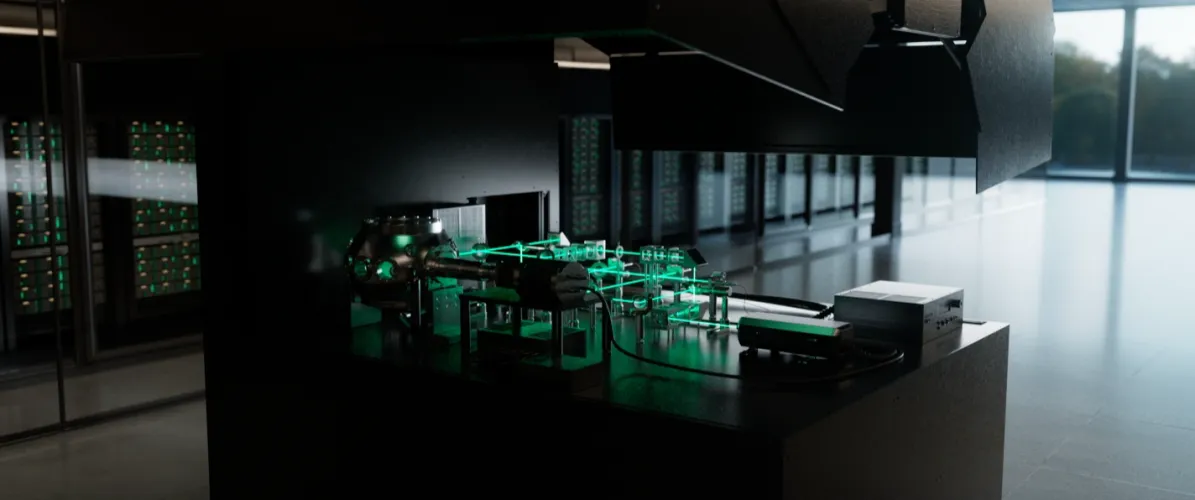

In 2018, Proserv responded to an industry challenge instigated by ORE Catapult around addressing gaps in both the scrutiny and innovation regarding the serious problem of cable failures. So, we engaged our subsea heritage and reputation for controls provision and integration, alongside our agnostic technology positioning, to collaborate with other experts, in power systems instrumentation (Synaptec) and subsea power cable engineering and management (BPP Cable Solutions), to build a holistic real-time monitoring solution, known as ECG™. Our system can deliver the necessary visualisation of cable asset condition and performance to reduce both downtime and OpEx, as expected by an industry on the move.

We saw this challenge as an opportunity to innovate – by utilising fibre optic sensing, to which we were already accustomed due to our legacy in the subsea space. Adopting the same mindset, technology and integration capabilities, we looked to apply that template in offshore wind. The evolution of ECG™ does not represent a diversification or a transition, but rather a continuation of our expertise.

Traditionally in offshore wind, operations and maintenance (O&M) strategies are based around regular scheduled procedures to assess infrastructure that is only partially instrumented, requiring the deployment of personnel and vessels.

At Proserv, we strongly advocate adopting a condition-based O&M strategy not only to reduce costs but to prioritise the integration of the innovation and capabilities of data, analytics and machine learning because, if the sector sticks to an out-dated periodic maintenance model, we risk not moving forwards sufficiently.

We are at a position where we can obtain whatever specific data sets we need through utilising the appropriate sensors. Although offshore wind is data heavy, it has taken a long time to get to a place where it realises it no longer has to keep on doing things the same way.

ECG™ offers operators better visibility and understanding of the live condition of their assets, empowering decision-making through the insights generated from data analytics, so alleviating the requirement for physical O&M inspections and the CO2 footprint of unnecessary journeys.

Visualisation is key

Later this year, our cable monitoring system will be deployed on Equinor’s Hywind Scotland floating wind farm. This is an exciting and unique opportunity for us as very little is known yet about the condition and integrity of dynamic cables utilised in a floating wind environment.

If future generating capacity targets are to be met, floating wind will have to play a key part and presently the sector does not understand what the challenges are going to be when it comes to operating and owning cables on a 25-year floating wind project as there are no tangible current data reference points.

The data harnessed and analysed by ECG™ will provide that vital and accessible visualisation to operators.

The bottom line, whether floating or fixed, is that the industry urgently requires better cable management philosophies. Asset owners need to embrace the power of data analytics, and the insights generated from that. These can identify potential problems before they arise, enable better allocation of expenditure and optimise O&M schedules. This is what the industry demands as it gears up for accelerated growth.

Published: 14-06-2022