Cold cutting saw targets land based decom, demolition and scrap recovery projects

Subsea cutting technology specialist Decom Engineering (Decom) has launched a new range of onshore hydraulic Chopsaws aimed at the civil engineering, demolition and decommissioning sectors.

TorqCut draws on Decom’s long track record of subsea cutting project success to deliver land-based cold-cutting solutions for piles, pipelines, demolition materials and more – eliminating the heat, fumes, HSE risks and overcutting associated with traditional methods.

Decom Engineering managing director, Nick McNally, explained: “Our cutting technology is well established in extreme subsea environments and now we are bringing that same DNA of reliability and precision to the onshore market.”

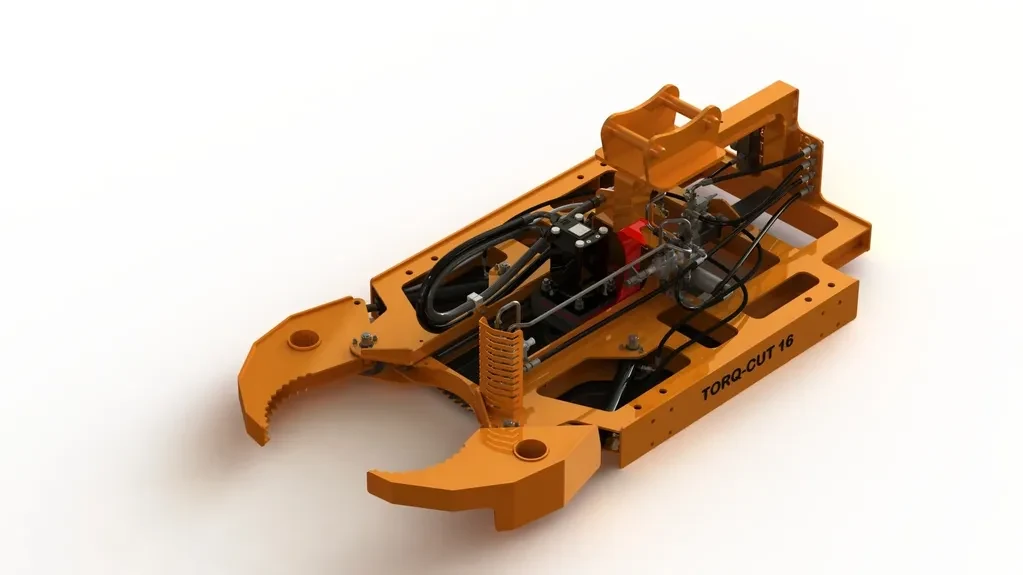

The TorqCut series is a versatile range of excavator-mounted attachments, with the initial launch including four models (TQ-10, TQ-16, TQ-24, and TQ-32) which are capable of cutting materials up to 32” diameter and can be deployed by excavators from 4 to 24 tonnes.

The new range is suitable for steel and concrete pile cutting, especially in urban or restricted-access sites where low noise and vibration is critical, and onshore pipeline and wellhead abandonment decommissioning workscopes.

In industrial demolition and scrap recovery, TorqCut provides precision dismantling of structures which contain high-value alloys like Duplex and Inconel, while preserving materials integrity to maximise the scrap value.

Nick McNally added: “TorqCut addresses the systematic failures of existing technologies by reducing or eliminating safety hazards associated with thermal cutting, and avoids the brute force approach of hydraulic sheers which are prone to hydraulic failure and blade destruction and which can also damage high-value alloys, so reducing their scrap value.

“There is a powerful economic proposition for end-users with TorqCut’s resilience directly mitigating the enormous financial risk of downtime caused by hydraulic failure, which can vary from between £50,000 to £100,000 per incident.”

He said: “For over a decade, Decom Engineering has mastered cutting technology in the most unforgiving subsea environments, where failure is not an option. TorqCut will offer the same ethos of bulletproof reliability to the onshore civil engineering and demolition industries.

“Contractors face enormous financial risk from equipment downtime and growing pressure to meet stringent safety and environmental standards. TorqCut is engineered to solve those challenges and will set a new standard for safer, cleaner, and more profitable operations.”

“Join the companies that smart energy professionals follow – because when you’re featured on OGV, the industry pays attention.”